Choosing the right flow indicator valve for your system is critical to optimizing operational efficiency and ensuring reliable performance. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 95 billion by 2026, with flow indicator valves playing a crucial role in various industries including oil and gas, water treatment, and chemical processing. These valves not only provide a visual confirmation of fluid flow, but also contribute to maintaining system integrity and safety. As industrial processes become increasingly complex, the demand for accurate and efficient flow monitoring solutions is evident. Therefore, selecting the appropriate flow indicator valve is essential, taking into account factors such as fluid type, flow rate, and system pressure to ensure compatibility and longevity. Understanding these parameters can lead to improved system performance and reduced downtime, highlighting the importance of informed decision-making in valve selection.

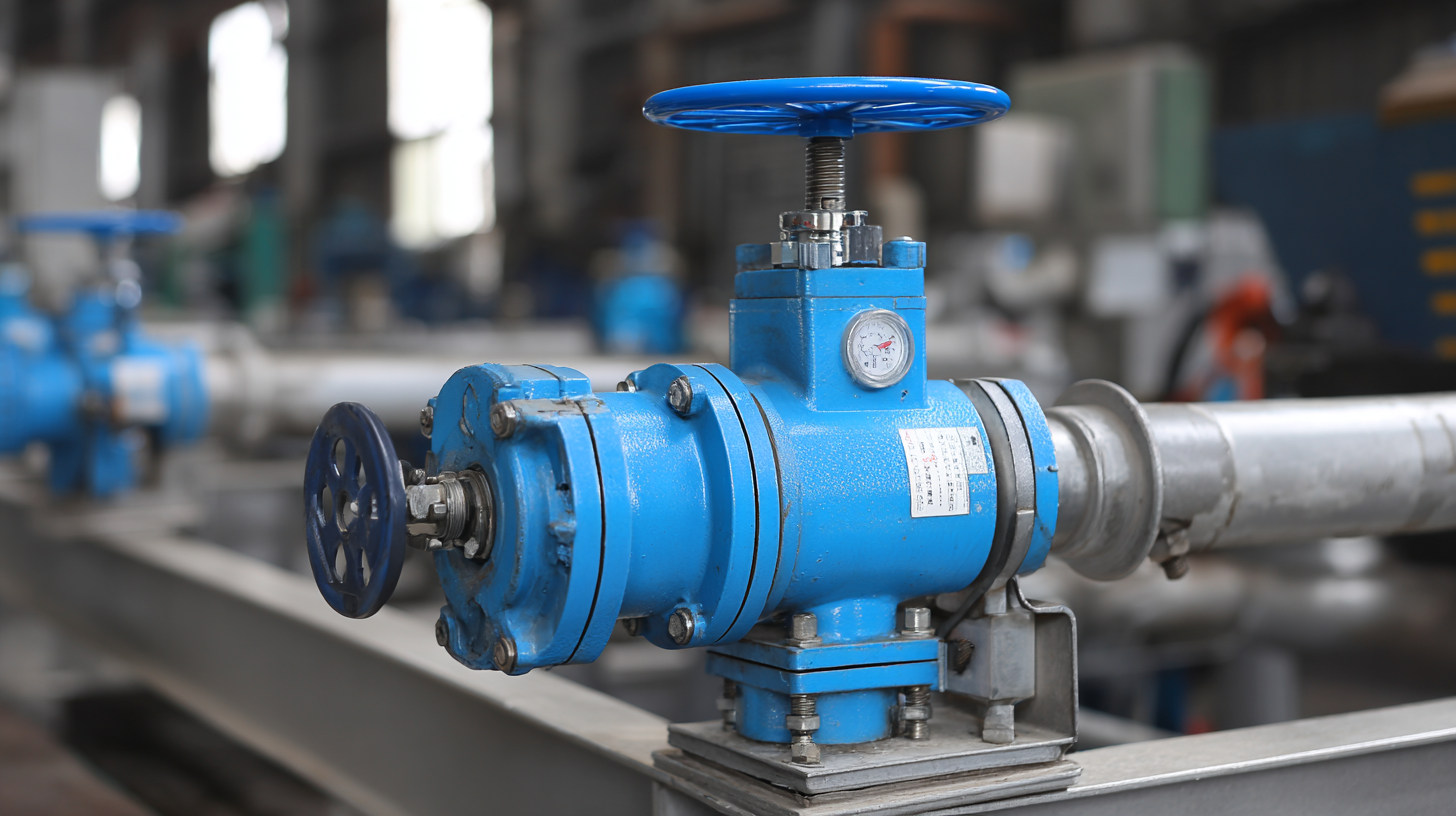

Flow indicator valves play a critical role in monitoring and managing fluid movement within various systems. These valves not only indicate the direction of flow but also help in identifying potential issues such as blockages or flow inconsistencies. Understanding their functionality is essential for ensuring smooth operations and maintaining system integrity. Typically, these valves are equipped with visible indicators, which may be mechanical, electronic, or visual, allowing operators to easily assess the flow status at a glance.

Choosing the right flow indicator valve involves assessing the specific needs of your system, including the type of fluid being handled, pressure requirements, and temperature limits. Different applications may demand varying materials and designs for optimal performance. For example, a transparent body may be suitable for monitoring water flow, while a robust metal construction may be required for high-pressure gas systems. Ultimately, selecting a flow indicator valve that aligns with your system's functionality will enhance efficiency and reliability, ensuring that any anomalies can be promptly addressed.

Choosing the right flow indicator valve involves assessing the specific needs of your system, including the type of fluid being handled, pressure requirements, and temperature limits. Different applications may demand varying materials and designs for optimal performance. For example, a transparent body may be suitable for monitoring water flow, while a robust metal construction may be required for high-pressure gas systems. Ultimately, selecting a flow indicator valve that aligns with your system's functionality will enhance efficiency and reliability, ensuring that any anomalies can be promptly addressed.

When selecting the right flow indicator valve for your system, it’s crucial to evaluate the various types available in the market. Flow indicator valves can be broadly categorized into several types, such as transparent sight glass valves, paddle flow indicators, and electronic flow meters. Each type serves distinct purposes and is suited for different applications. For instance, transparent sight glass valves provide a clear view of the fluid flow, making them ideal for processes requiring visual monitoring. They are commonly used in water treatment facilities and food processing plants.

On the other hand, paddle flow indicators utilize a mechanical paddle that rotates with the flow, allowing for a more straightforward determination of flow rate. These are particularly beneficial in applications where electronic monitoring isn't feasible. Additionally, electronic flow meters offer precision measurements and the ability to integrate with control systems, which can enhance the efficiency of automated processes. Ultimately, the choice of flow indicator valve should be guided by factors such as the nature of the fluid, required accuracy, installation environment, and maintenance considerations, ensuring optimal performance for the system.

When selecting a flow indicator valve for your system, understanding the key specifications is crucial. First, consider the flow rate and the pressure range that your application requires. Ensuring the valve can handle the maximum flow rate without significant pressure drop is essential for maintaining system efficiency. Additionally, check for compatibility with the fluid types involved, whether they are corrosive, high-temperature, or require specific material considerations.

**Tips:** Always consult the flow characteristics of the valve under different conditions. This helps in understanding how the valve will perform in real-world applications, preventing issues like cavitation or excessive wear.

Another important specification is the valve size. Accurate sizing can prevent issues with turbulence and pressure loss. It's beneficial to look at the connection types as well, ensuring they match your piping system for easy installation and maintenance.

**Tips:** Utilize flow simulation tools if available, as they can help visualize how changes in valve specifications can affect system performance. This proactive approach can save time and costs in long-term operation.

This chart compares various key specifications of flow indicator valves suitable for different applications. Specifications include Flow Range (L/min), Pressure Rating (bar), and Temperature Tolerance (°C).

When selecting the right flow indicator valve for your system, assessing compatibility with your existing setup is crucial. A report by the Flow Measurement Bureau suggests that approximately 35% of system failures occur due to misalignment between components, underscoring the need for thorough compatibility checks. Understanding the specifications of your current system, such as pressure ratings, temperature ranges, and fluid characteristics, will help in choosing a valve that does not disrupt the operational efficiency.

Moreover, industry standards highlighted in the International Society of Automation (ISA) suggest that flow measurement accuracy is significantly affected by improper valve selection. For instance, using a valve with a mismatch in connection diameter can lead to turbulence, increasing risk of wear and reducing lifespan by up to 40%. Therefore, ensuring that your flow indicator valve matches your system’s specifications will not only optimize performance but also contribute to long-term reliability and cost efficiency in maintenance.

When it comes to maintaining flow indicator valves, regular inspection and timely replacement are crucial for ensuring optimal system performance. A recent industry report by the Fluid Control Association indicates that nearly 18% of flow system failures are directly linked to neglected valve maintenance. Operators should establish a routine maintenance schedule that includes checking for leaks, ensuring proper sealing, and confirming that the indicator mechanisms are functioning correctly. By addressing these components, businesses can significantly reduce downtime and related costs.

In terms of replacement considerations, understanding the specific requirements of your system is essential. According to a study published by the American Society of Mechanical Engineers, choosing the wrong valve type can lead to over 25% increased energy consumption in flow systems. It’s important to select flow indicator valves that match the fluid characteristics and pressure ratings of your equipment. Additionally, compatibility with existing components can minimize the need for extensive modifications during replacement, ultimately streamlining the entire process. Investing in quality valves with reliable indicators can yield long-term savings and efficiency improvements in operations.