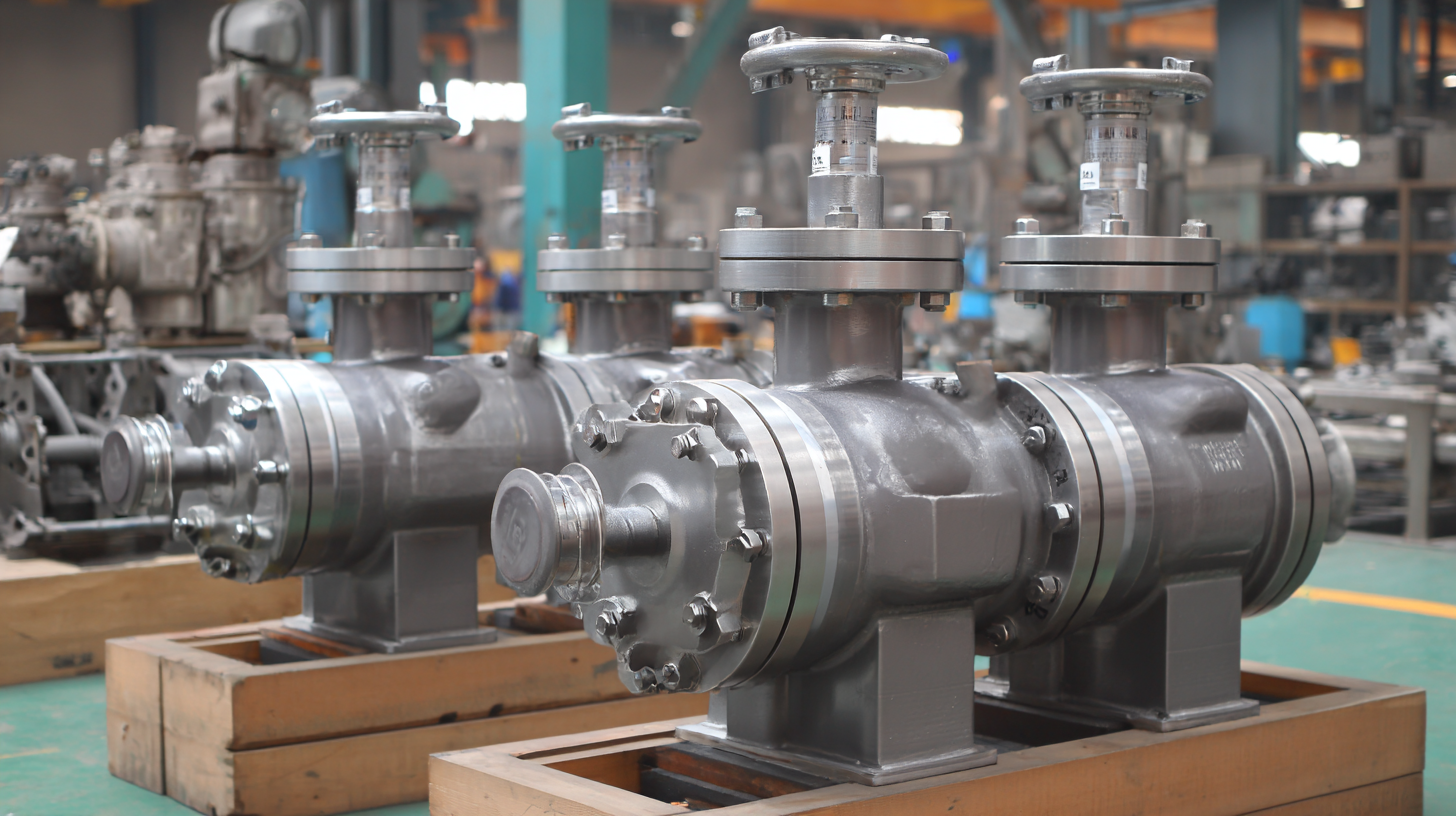

In industrial applications where chemical resistance and durability are paramount, selecting the right PFA lined valves is critical. According to a recent industry report by Market Research Future, the global market for lined valves is expected to witness significant growth, driven by increasing demand in sectors such as chemical processing, pharmaceuticals, and food and beverage. PFA lined valves, known for their exceptional corrosion resistance and ability to handle aggressive media, play an essential role in maintaining operational efficiency and safety.

When choosing PFA lined valves, factors such as temperature tolerance, pressure ratings, and compatibility with specific chemicals should be meticulously evaluated. By understanding the unique properties and applications of PFA lined valves, engineers and procurement managers can make informed decisions that enhance performance and reduce downtime in their operations.

In industrial applications, particularly those involving corrosive environments, the selection of appropriate valves is crucial. PFA lined valves offer a unique solution, providing excellent resistance to aggressive chemicals and high temperatures. According to a recent report by the Chemical Processing Association, approximately 50% of industrial equipment failures are attributed to corrosion, highlighting the importance of using materials that can withstand harsh conditions. PFA, or perfluoroalkoxy, is particularly effective, boasting a temperature tolerance of up to 200°C and a pH range of 0-14, making it an ideal choice for various corrosive substances.

Furthermore, the durability and longevity of PFA lined valves can significantly reduce maintenance costs and downtime. The American Society for Testing and Materials (ASTM) stated that industries utilizing lined valves experience up to a 30% reduction in maintenance-related expenses over a five-year period. By understanding the critical role of PFA lined valves in mitigating corrosion risks, industries can enhance operational efficiency and improve safety standards, ultimately leading to a more sustainable operational model in corrosive applications.

| Dimension | Description | Application | Material Compatibility | Temperature Range (°C) |

|---|---|---|---|---|

| 1/2" | Small PFA lined valve for low flow systems | Chemical processing, water treatment | Strong acids, alkalis | -20 to 150 |

| 1" | Standard PFA lined valve suitable for various fluids | Food processing, pharmaceuticals | Hydrochloric acid, sulfuric acid | -20 to 200 |

| 2" | Large PFA lined valve for high flow applications | Petrochemical industry, wastewater | Chlorine, concentrated acids | -20 to 120 |

| 3" | Heavy-duty PFA lined valve for industrial systems | Chemical manufacturing, plant processes | Strong oxidizers, solvents | -20 to 180 |

When selecting PFA lined valves for chemical processing, several key factors must be considered to ensure optimal performance and longevity.

Firstly, the compatibility of the valve materials with the specific chemicals being processed is paramount.

PFA, or perfluoroalkoxy alkanes, offers excellent resistance to corrosive substances, but understanding the

chemical characteristics—such as temperature, pressure, and concentration—is crucial to prevent any adverse reactions that could lead to valve failure.

Another significant factor is the valve's pressure rating and temperature tolerance.

Industrial applications often involve extreme conditions, and PFA lined valves must be able to withstand these without compromising their integrity.

Evaluating the maximum operating pressure and temperature, alongside the typical service conditions, will help in choosing valves that ensure reliable and safe operation.

Additionally, it’s essential to consider the installation space and the design of the valve itself. Proper fit and alignment are vital to avoid leaks and ensure efficiency in your chemical processes.

PFA lined valves have gained popularity in industrial applications due to their superior chemical resistance and low friction properties compared to other lining materials like PTFE and rubber. According to a recent market analysis report by ResearchAndMarkets, the demand for PFA lined valves is expected to grow by 7% annually, propelled by their effectiveness in handling corrosive substances. PFA's ability to withstand temperatures up to 260°C and resistance to a wide range of chemicals makes it an ideal choice for industries such as pharmaceuticals, oil and gas, and chemical processing.

When selecting PFA lined valves, it is crucial to consider the operational environment and the specific chemicals involved. Tips for making an informed choice include reviewing compatibility charts to identify how well PFA withstands certain chemicals compared to alternatives. Additionally, assessing the valve's pressure rating and temperature limits can prevent failures in harsh conditions, ensuring operational reliability and safety.

Another vital aspect is the longevity of the lining material. Data from the Chemical Engineering Magazine indicates that PFA lined valves can double the life expectancy of PTFE counterparts in highly corrosive environments. Thus, investing in PFA lined valves not only enhances efficiency but also reduces maintenance costs in the long run.

When selecting PFA lined valves for industrial applications, understanding their performance specifications—particularly pressure and temperature ratings—is crucial. PFA, or perfluoroalkoxy, is renowned for its outstanding chemical resistance and thermal stability, making it an excellent choice for handling corrosive substances. However, the effectiveness of these valves is significantly influenced by their pressure and temperature ratings. Each application will have specific requirements that these ratings must meet to ensure safety and operational efficiency.

For instance, a valve's pressure rating determines the maximum pressure it can withstand without failing, while the temperature rating indicates the highest and lowest temperatures at which the valve can operate effectively. When evaluating a PFA lined valve, it’s essential to consult the manufacturer's specifications to ensure that both the pressure and temperature ratings align with the operational conditions of your specific application. Selecting a valve with inadequate ratings can lead to malfunctions, potentially resulting in costly downtime or hazardous incidents. Therefore, a comprehensive assessment of these performance specifications is vital for achieving reliable and efficient industrial operations.

Selecting the appropriate PFA lined valves for industrial applications is crucial not only for operational efficiency but also for long-term cost savings. According to a report by MarketsandMarkets, the global market for fluoropolymer coatings is expected to reach $8 billion by 2024, indicating a growing recognition of the value these materials bring to various industries. PFA lined valves offer excellent resistance to corrosion and chemical attack, which significantly lowers maintenance costs. The initial investment in PFA lined valves may be higher than conventional options, but the longevity and reduced frequency of replacements result in substantial savings over time.

Moreover, a study published by the Chemical Processing Industry reveals that switching to PFA lined valves can lead to a reduction in operational downtimes by up to 30%. This reduction is directly linked to the reliability of PFA materials in harsh environments. For industries where safety and compliance are paramount, the right valve selection can mitigate risks associated with leaks and failures, further contributing to financial efficiency. In many cases, the total cost of ownership—including maintenance, replacement, and potential loss due to downtime—demonstrates that PFA lined valves offer a favorable return on investment over their lifecycle.