Choosing the right water flow sight glass can significantly enhance the efficiency and safety of your fluid monitoring systems. This essential component not only allows you to visually assess the flow of liquids but also plays a crucial role in maintaining optimal operating conditions in various applications. With a plethora of options available on the market, selecting the ideal water flow sight glass tailored to your specific requirements can be overwhelming.

In this ultimate guide, we will explore five essential tips to help you navigate through the complexities of choosing the best water flow sight glass for your needs. Whether you are looking for durability, compatibility, or ease of installation, understanding these key factors will empower you to make an informed decision that meets both your operational demands and budget.

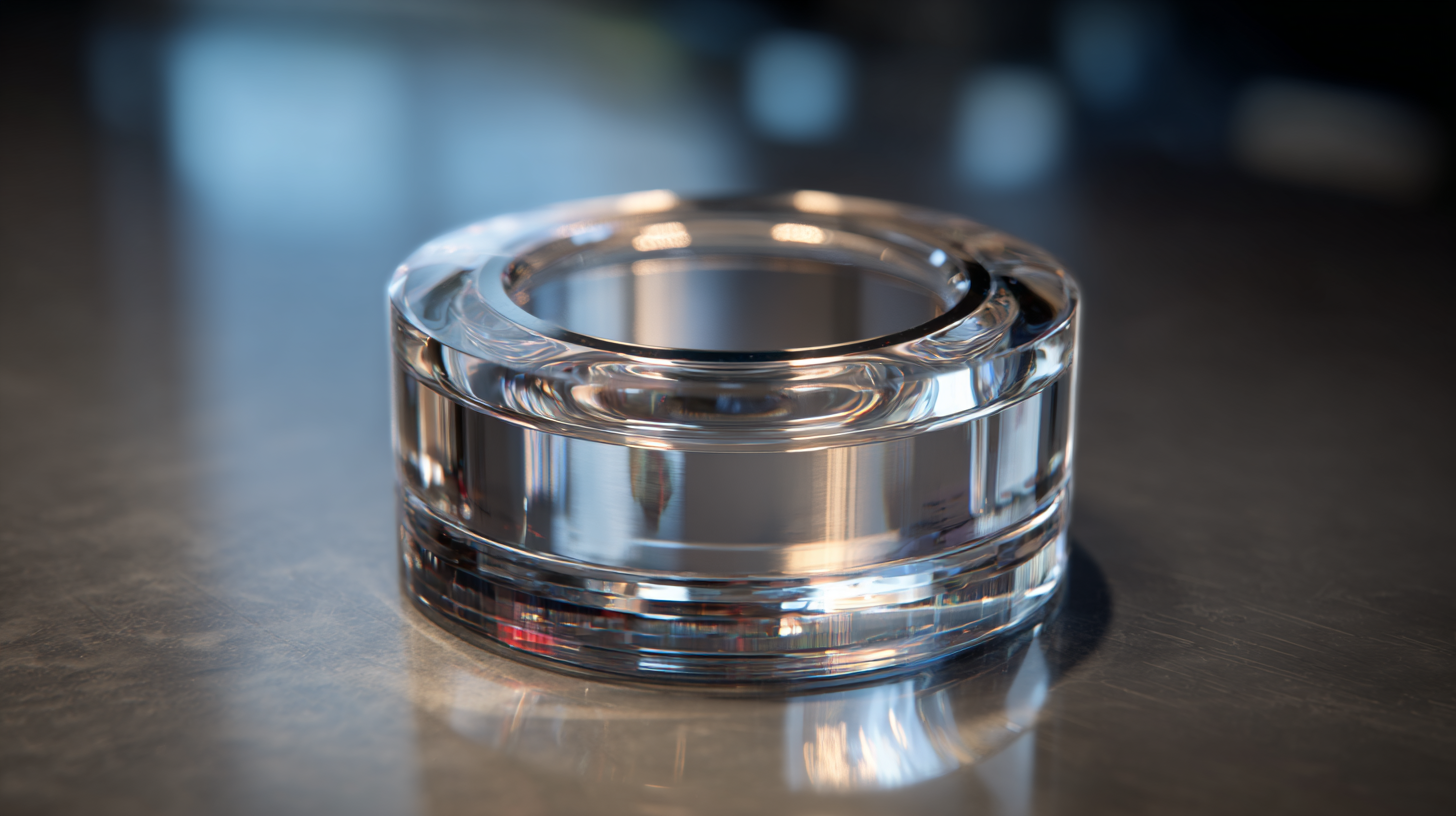

When selecting a water flow sight glass, several key features should guide your decision. First, consider the material of the sight glass. Common materials include glass, acrylic, and stainless steel. Each material has its advantages; for instance, glass offers high clarity and resistance to corrosion, while acrylic is lighter and impact-resistant. The right choice will depend on your specific application and the environmental conditions it will face.

Next, pay attention to the size and connection type of the sight glass. It’s essential to ensure that the dimensions match your piping system to prevent issues like leaks or improper fittings. Additionally, check whether the sight glass requires flanged, threaded, or quick-disconnect connections to fit seamlessly with your existing setup. Lastly, don’t overlook the importance of pressure and temperature ratings. Make sure the sight glass can withstand the operational pressures and temperatures of your system to ensure safety and longevity.

When selecting the best water flow sight glass for your specific needs, it’s crucial to understand the various types available in the market. Primarily, sight glasses fall into two categories: tubular and flat-panel designs.

Tubular sight glasses are often favored for their simplicity and ability to provide clear visual flow indications, making them ideal for lower pressure applications. In contrast, flat-panel sight glasses are more robust and can handle higher pressures and temperatures, which is essential in industrial settings. According to the Fluid Control Systems Market Report 2023, demand for durable materials in sight glasses, such as borosilicate glass and polymer, is on the rise due to increased operational stress in modern applications.

Tubular sight glasses are often favored for their simplicity and ability to provide clear visual flow indications, making them ideal for lower pressure applications. In contrast, flat-panel sight glasses are more robust and can handle higher pressures and temperatures, which is essential in industrial settings. According to the Fluid Control Systems Market Report 2023, demand for durable materials in sight glasses, such as borosilicate glass and polymer, is on the rise due to increased operational stress in modern applications.

Furthermore, the selection of sight glasses is not just about the design but also the installation and maintenance needs. Some models come equipped with integrated cleaning systems, which can significantly reduce downtime and maintenance costs, particularly in sectors like water treatment and food processing. A study by the International Journal of Water Management found that effective flow visibility can enhance operational efficiency by up to 20%. Choosing the right type based on these factors can not only optimize performance but also ensure safety and reliability in various water management applications.

When selecting a water flow sight glass, the choice of materials plays a critical role in determining both durability and performance. According to a report by the Fluid Controls Association, the wrong material can lead to premature failure, risking both system integrity and safety. For instance, standard glass sight glasses offer basic visibility but can shatter under high pressure or temperature, whereas tempered glass can withstand stronger conditions, reducing the likelihood of unexpected breaks.

Additionally, the selection of materials such as stainless steel versus plastic significantly affects not only the lifespan of the sight glass but also its resistance to corrosion and chemical damage. The Society of Chemical Engineers highlights that corrosion-resistant materials can enhance the longevity of equipment, with stainless steel proving to last up to 10 times longer than conventional plastics in aggressive environments. Therefore, when choosing a sight glass, it is crucial to consider both the operational conditions and the material properties to ensure optimal performance and minimize maintenance costs.

When selecting a water flow sight glass, understanding the importance of size and installation compatibility is crucial for optimizing its performance in your specific application. First and foremost, the diameter of the sight glass should match the pipeline it will be installed in. An improper size can lead to flow restrictions or even system failure. Ensuring that the sight glass dimensions align with your piping can maximize fluid visibility and minimize the risk of leaks or pressure build-up.

Installation compatibility is equally important. Evaluate the existing setup to determine whether a threaded, flanged, or welded sight glass would be most appropriate. Each installation type has its own advantages depending on the nature of the system and its operating conditions. For instance, flanged sight glasses provide easier access for maintenance, while welded varieties offer a more secure and permanent solution. By carefully considering these factors, you can ensure that you select a sight glass that will function effectively and enhance the efficiency of your water flow monitoring system.

When it comes to purchasing a water flow sight glass, balancing cost and quality is paramount. A common pitfall is focusing solely on the price tag, which can lead to poor decisions. Investing in a high-quality sight glass often pays off in the long run, as it reduces maintenance issues and enhances safety. Prioritize finding materials that can withstand the pressures and temperatures of your application, which can prevent costly breakdowns or leaks down the line.

One essential tip is to compare the features of various brands. Look for options that offer durable construction and clarity, ensuring that you can monitor water flow effectively. Additionally, consider the manufacturer’s reputation. Opting for well-established brands might cost a bit more initially, but their reliability can save you money over time due to decreased potential for failure.

Lastly, don't overlook customer reviews and industry recommendations. These insights provide valuable information about how products perform in real-world conditions. By weighing the balance of cost versus quality through these tips, you can make an informed decision that meets your operational needs without compromising on safety and efficiency.

| Feature | Description | Cost Range | Quality Rating |

|---|---|---|---|

| Material | Common materials include glass, acrylic, and stainless steel | $30 - $150 | High |

| Size | Available in various diameters and lengths | $20 - $100 | Medium |

| Connection Type | Includes threaded, flanged, and welded connections | $25 - $140 | Variable |

| Temperature Resistance | Some models are designed for high-temperature applications | $50 - $200 | High |

| Pressure Rating | Important for applications with high pressure | $40 - $160 | High |